Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

We design and manufacture high-performance pharmaceutical machinery ensuring precision, safety, and global compliance.

We are a trusted manufacturer and supplier of pharmaceutical machinery, delivering reliable, efficient, and GMP-compliant solutions to clients worldwide. Our focus is on innovation, precision engineering, and long-term performance.

Full-scale production adhering to Good Manufacturing Practice (GMP) standards for solid, liquid, and sterile dosage forms.

Blister packaging, bottling, and labeling services with serialization for complete track and trace compliance.

In-house analytical testing, stability studies, and documentation support for global regulatory submissions.

Sterile manufacturing and lyophilization services for vials, syringes, and other parenteral products.

Delivering high-performance digital solutions where data meets design.

Adhering to strict international guidelines to ensure every batch meets global safety and quality certifications.

Implementing advanced waste management and water treatment systems to minimize our ecological footprint while maximizing output efficiency.

Dedicated research labs focused on developing stable, effective, and bioavailable pharmaceutical products for diverse therapeutic areas.

Ensuring end-to-end transparency and temperature-controlled logistics to maintain product potency from the factory to the pharmacy.

Utilizing advanced automated machinery to maintain 100% uniformity across large-scale solid, liquid, and semi-solid formulations.

Prioritizing human safety through rigorous training programs and automated safety protocols to maintain a secure, high-performance manufacturing environment.

Ensuring active pharmaceutical ingredients align perfectly with clinicalrequirements to improvepatient safety and drug efficacy.

Understanding how well each production cycle contributes to overall therapeutic performance and market reliability.

Optimizing energy consumption and waste recovery to support long-term environmental responsibility in chemical processing.

Building operational models that adapt to growth while maintaining strict cost control and consistent performance stability.

Evaluating how efficiently our production lines adapt to shifting market demands and urgent healthcare requirements without compromising quality.

Maintaining optimal adherence to WHO-GMP and international standards to prevent batch disruptions and support global health safety.

Our lead engineers bring decades of pharmaceutical innovation to your facility. We don’t just sell machines, we provide the intellectual partnership needed to optimize your production and solve complex manufacturing challenges.

Precision filling of hard & soft gelatin capsules. From R&D batches to commercial scale with weight variation control.

High-speed compression coating for solid oral doses. Compliant with global pharmacopeia standards for immediate & modified release.

Aseptic filling for vials, syringes, and cartridges. Full lyophilization services for parenteral products in Class A/B environments.

Syrups, suspensions, and oral solutions manufacturing. Complete homogeneity assurance and stability testing.

Engineered for low energy consumption and reduced material waste, helping your facility reach its sustainability goals without sacrificing speed.

Our machines feature a modular architecture, allowing you to easily upgrade or swap components as your production needs grow and evolve.

High-level access control with biometric logging to ensure that only authorized personnel can change critical machine parameters.

Delivering high-accuracy manufacturing solutions for complex pharmaceutical production.

Our machines feature micron-level precision to ensure consistent dosage and zero-defect output for every batch.

Full adherence to international safety and manufacturing standards.

Designed and built to meet strict USFDA, EU-GMP, and WHO guidelines for seamless regulatory approval.

Tailor-made machinery designed for your specific production requirements.

From prototype to production, we integrate the latest automation and IoT tracking into your manufacturing line.

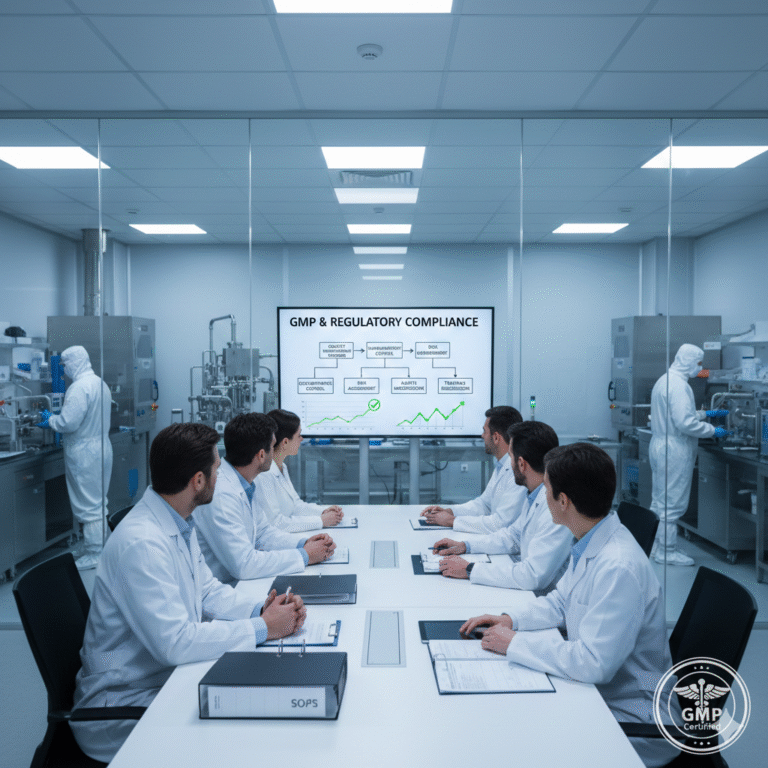

OUR QUALITY ADVANTAGE

Our integrated quality management system ensures every product batch meets the highest standards of safety, efficacy, and consistency. We are committed to maintaining full compliance across all regulatory environments for pharmaceutical and biotech clients.

Our manufacturing sites are FDA, EMA, and PIC/S approved with comprehensive quality management systems in place.

Complete batch records, electronic data capture, and serialization ensuring full supply chain transparency and audit readiness.

Real-time environmental monitoring, in-process controls, and stability studies to guarantee product integrity throughout the lifecycle.

Regularly audited by major global pharmaceutical companies

We provide integrated solutions from API handling to finished dosage forms. Our GMP-certified facilities and quality-by-design approach ensure scalable, compliant production for solid, liquid, and sterile pharmaceuticals, turning complex molecules into reliable therapies.

Beyond production, we are your strategic ally. From process development and tech transfer to regulatory support and commercial supply, we partner at every stage to de-risk your journey, optimize costs, and secure sustainable market success.

As a certified pharmaceutical manufacturing partner,

we combine technical expertise with regulatory excellence

to deliver scalable, compliant production solutions for

global markets.

High-performance machinery designed for precision, compliance, and reliability.

Engineered for high-capacity production, this automated rotary system provides a multi-stage 360-degree sterile cleaning process for glass and plastic containers. By integrating high-pressure air and water jets, it ensures total removal of micro-particulates while adhering to global cGMP hygiene standards. This critical sterilization stage guarantees product purity and eliminates contamination risks before the filling process.

Precision-engineered for high-volume production, our sensor-based counting system ensures 100% accuracy for various tablet shapes and sizes. Built with a cGMP-compliant stainless steel design, it delivers rapid, contamination-free bottling at speeds of up to 1,000 units per minute.

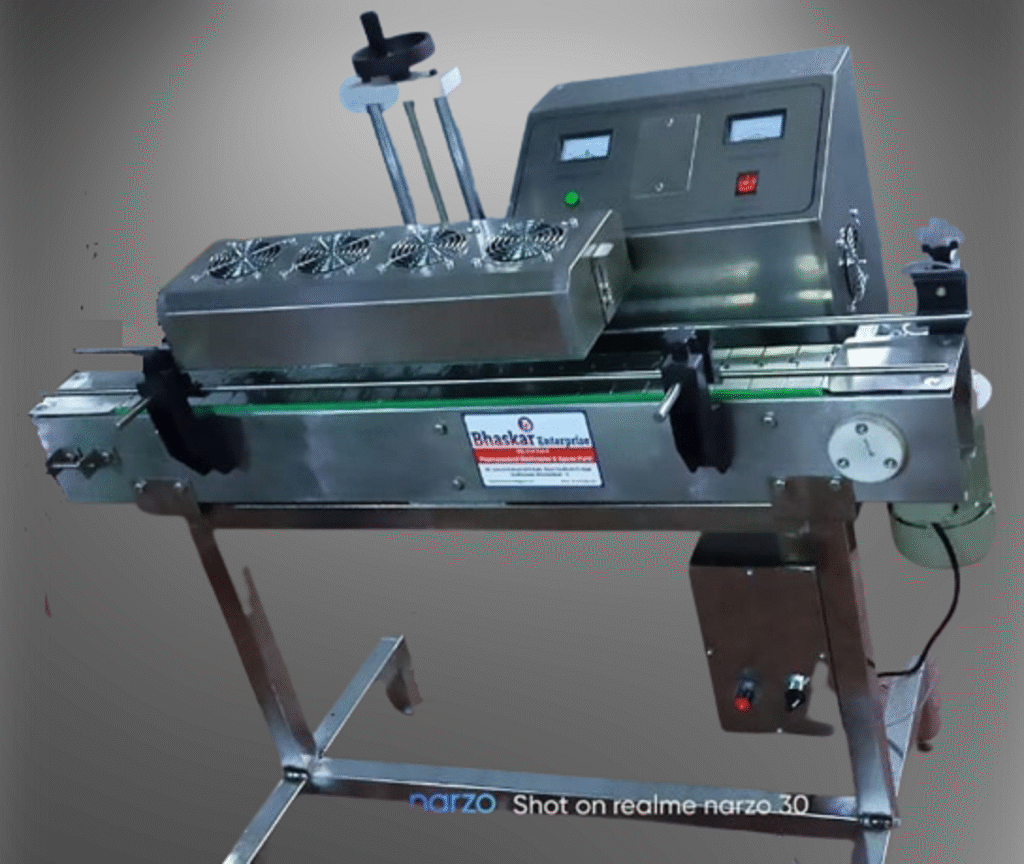

Ensure product integrity with our high-frequency induction sealing technology. Designed for rapid, non-contact hermetic sealing, this machine provides leak-proof security and tamper-evident protection for pharmaceutical bottles and containers.

These metrics reflect our dedication to quality, reliability, and partnership in pharmaceutical manufacturing. Each number represents our ongoing commitment to delivering safe, effective medicines to global markets.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.