Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

We manufacture high-performance industrial machinery built for precision, durability, and efficiency. Our solutions are engineered to meet modern industry demands with uncompromising quality. From concept to completion, we focus on reliability you can trust. Powering industries with innovation that lasts.

Delivering advanced machinery solutions that drive productivity and long-term value. We combine engineering expertise with cutting-edge technology to serve diverse industries. Every machine is designed for performance, safety, and consistency. Building smarter industries for a stronger future.

Full-scale production adhering to Good Manufacturing Practice (GMP) standards for solid, liquid, and sterile dosage forms.

Blister packaging, bottling, and labeling services with serialization for complete track and trace compliance.

In-house analytical testing, stability studies, and documentation support for global regulatory submissions.

Sterile manufacturing and lyophilization services for vials, syringes, and other parenteral products.

Delivering high-performance digital solutions where data meets design.

Adhering to strict international regulatory standards, compliance protocols, and guidelines to ensure every batch meets global safety and quality certifications.

Implementing advanced waste management and water treatment systems to minimize our ecological footprint while maximizing output efficiency.

Dedicated research labs equipped with advanced capabilities focused on developing stable, effective, and bioavailable pharmaceutical products for diverse therapeutic areas.

Ensuring end-to-end transparency and temperature-controlled logistics to maintain product potency from the factory to the pharmacy.

Utilizing advanced automated machinery and precision controls to maintain 100% uniformity across large-scale solid, liquid, and semi-solid formulations.

Prioritizing human safety through rigorous training programs and automated safety protocols to maintain a secure, high-performance manufacturing environment.

Measuring what matters begins with a deep commitment to accuracy and consistency.

Every process is designed to deliver reliable, repeatable results at every stage of production.

We focus on precision-driven systems that ensure quality is never compromised.

Advanced monitoring and control technologies guide each operation.

Strict adherence to global regulatory and compliance standards is maintained throughout.

Data-driven insights support informed decisions and continuous improvement.

Our processes are built to minimize risk and maximize operational efficiency.

Each product reflects our dedication to safety, performance, and purity.

Quality is measured not only by output, but by trust earned.

This is how we define pharmaceutical excellence.

Ensuring active pharmaceutical ingredients align perfectly with clinicalrequirements to improvepatient safety and drug efficacy.

Understanding how well each production cycle contributes to overall therapeutic performance and market reliability.

Optimizing energy consumption and waste recovery to support long-term environmental responsibility in chemical processing.

Building operational models that adapt to growth while maintaining strict cost control and consistent performance stability.

Evaluating how efficiently our production lines adapt to shifting market demands and urgent healthcare requirements without compromising quality.

Maintaining optimal adherence to WHO-GMP and international standards to prevent batch disruptions and support global health safety.

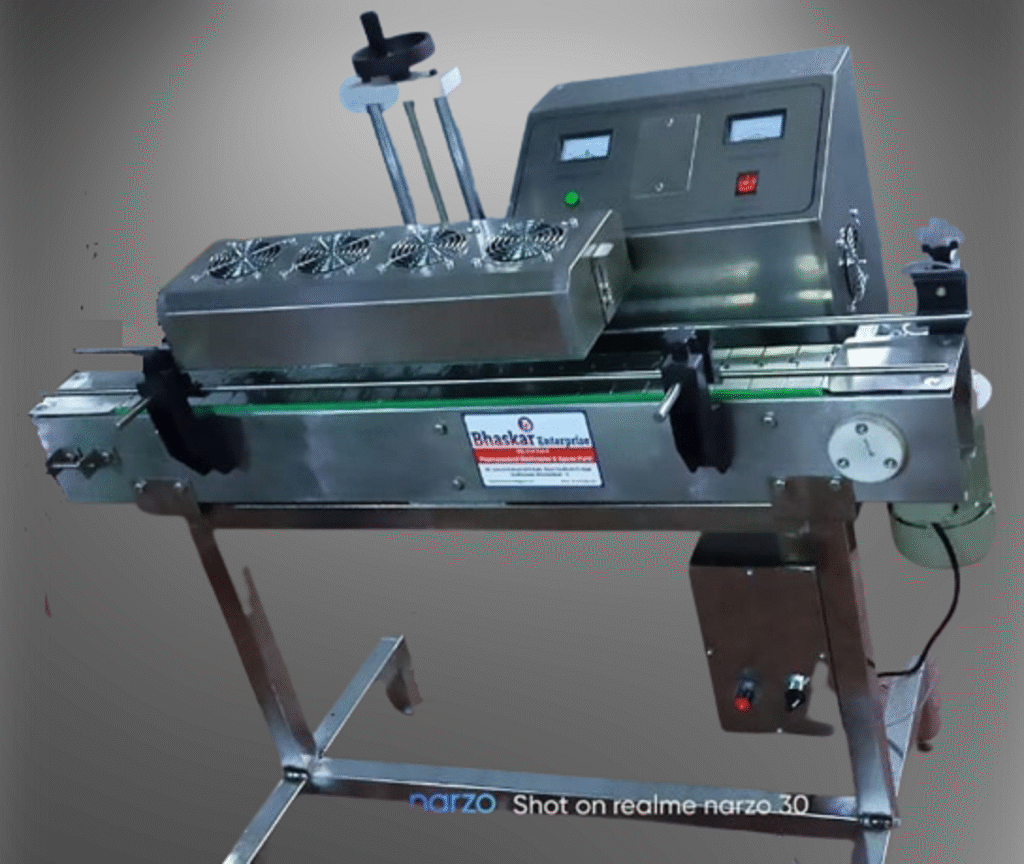

High-performance machinery designed for precision, compliance, and reliability.

Engineered for high-capacity production, this automated rotary system delivers 360° multi-stage sterile cleaning for glass and plastic containers. High-pressure air and water jets ensure complete particulate removal while meeting cGMP hygiene standards before filling.

Precision-engineered for high-volume production, this sensor-based system accurately counts tablets of various shapes and sizes. Its cGMP-compliant stainless steel design enables fast, contamination-free bottling up to 1,000 units per minute.

Ensure product integrity with our high-frequency induction sealing technology. Designed for rapid, non-contact hermetic sealing, this machine provides leak-proof security and tamper-evident protection for pharmaceutical bottles and containers.

Driving pharmaceutical innovation through precision-driven development.

Upholding global quality standards to ensure safe, reliable, and effective formulations.

Delivering high-performance APIs through cutting-edge manufacturing processes.

Expanding beyond pharmaceuticals with technology-enabled, future-focused solutions.

These metrics reflect our dedication to quality, reliability, and partnership in pharmaceutical manufacturing. Each number represents our ongoing commitment to delivering safe, effective medicines to global markets.